How HxGN EAM Keeps The World's Largest Machine Running Smoothly

How HxGN EAM helps CERN manage the world’s most complex machine and empower physicists to discover the secrets of the universe.

The birthplace of the World Wide Web and home to major scientific discoveries such as antimatter and the Higgs boson, the European Organization for Nuclear Research, or CERN, is a research institution like no other.

As the world’s largest research centre for particle physics, it provides 12,000 visiting scientists from top universities and research institutions around the world with the tools they need to study the fundamental particles of the universe. Some of these tools are the largest and most complex machines in the world.

Maximizing Uptime To Advance Science

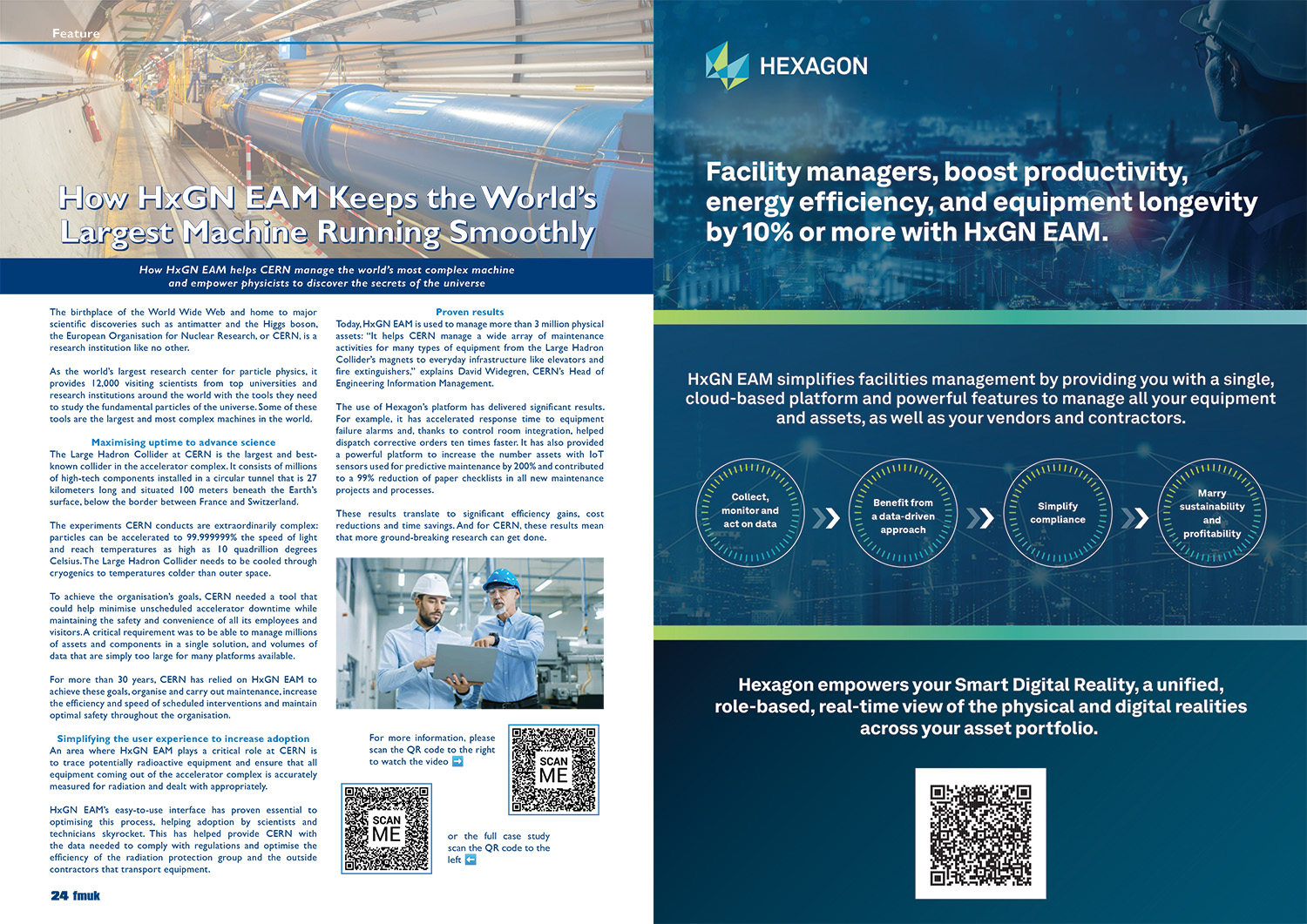

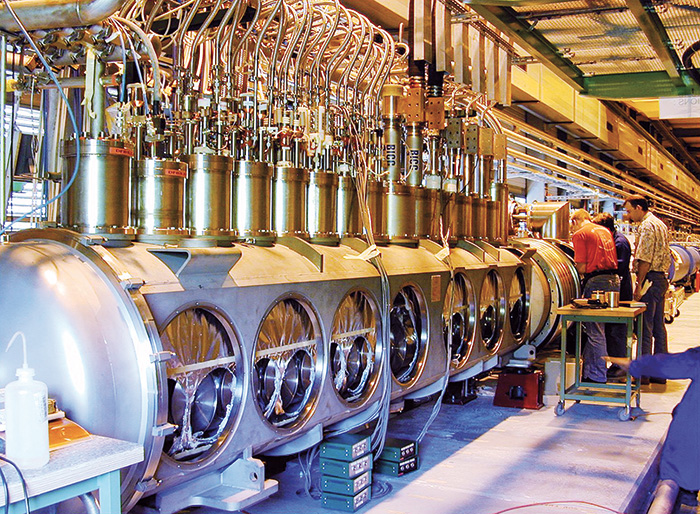

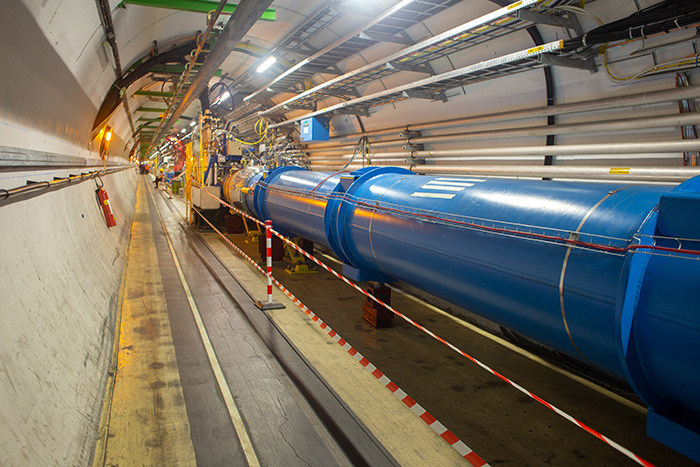

The Large Hadron Collider at CERN is the largest and best-known collider in the accelerator complex. It consists of millions of high-tech components installed in a circular tunnel that is 27 kilometres long and situated 100 metres beneath the Earth’s surface, below the border between France and Switzerland.

The experiments CERN conducts are extraordinarily complex: particles can be accelerated to 99.999999% the speed of light and reach temperatures as high as 10 quadrillion degrees Celsius. The Large Hadron Collider needs to be cooled through cryogenics to temperatures colder than outer space.

To achieve the organization’s goals, CERN needed a tool that could help minimize unscheduled accelerator downtime while maintaining the safety and convenience of all its employees and visitors. A critical requirement was to be able to manage millions of assets and components in a single solution, and volumes of data that are simply too large for many platforms available.

For more than 30 years, CERN has relied on HxGN EAM to achieve these goals, organize and carry out maintenance, increase the efficiency and speed of scheduled interventions and maintain optimal safety throughout the organization.

Simplifying The User Experience To Increase Adoption

An area where HxGN EAM plays a critical role at CERN is to trace potentially radioactive equipment and ensure that all equipment coming out of the accelerator complex is accurately measured for radiation and dealt with appropriately.

HxGN EAM’s easy-to-use interface has proven essential to optimizing this process, helping adoption by scientists and technicians skyrocket. This has helped provide CERN with the data needed to comply with regulations and optimize the efficiency of the radiation protection group and the outside contractors that transport equipment.

Proven Results

Today, HxGN EAM is used to manage more than 3 million physical assets: “It helps CERN manage a wide array of maintenance activities for many types of equipment from the Large Hadron Collider’s magnets to everyday infrastructure like elevators and fire extinguishers,” explains David Widegren, CERN’s Head of Engineering Information Management.

The use of Hexagon’s platform has delivered significant results. For example, it has accelerated response time to equipment failure alarms and, thanks to control room integration, helped dispatch corrective orders ten times faster. It has also provided a powerful platform to increase the number assets with IoT sensors used for predictive maintenance by 200% and contributed to a 99% reduction of paper checklists in all new maintenance projects and processes.

These results translate to significant efficiency gains, cost reductions and time savings. And for CERN, these results mean that more ground-breaking research can get done.

For more information, please watch the video here or read the full case study.

Click the article to enlarge it.