Hybrid Heating – A Practical Response For Refurbishing Environmentally Unfriendly Facilities

By Bill Sinclair, technical director, Adveco

According 2019 figures issued by the Department for Business, Energy and Industrial Strategy (BEIS), heating, cooling, ventilating, and providing hot water and lighting for the built environment makes business the third largest emitter, at 17%, of greenhouse gasses in the UK. To secure climate-neutral building stock by 2050, facility managers desperately need help to achieve practical and cost-effective sustainability.

While studies show that over the next two decades renewable energy sources (RES) - a mix of district heating, heat pumps, wind and solar energy - will be crucial to the energy supply in the heating market, we would lean towards more technology-open scenarios that not only predict large proportions of heat pumps, but also assume the use of gaseous fuels. Just as electricity is becoming greener so too can the gaseous fuels which will contain larger shares of renewable ‘green’ hydrogen gas and other synthetic fuels by 2050. This supports the adoption of a hybrid approach, which we not only see as more practical, but is both cost effective and less influenced by the volatility of a RES electricity only approach.

Why Take The Hybrid Route?

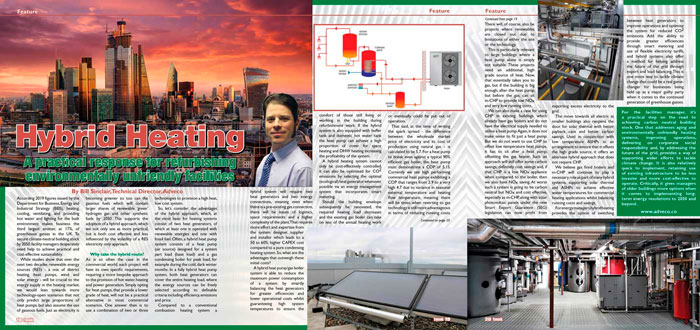

As is so often the case in the commercial world, each project will have its own specific requirements, requiring a more bespoke approach to the provision of hot water, heating and power generation. Simply opting for heat pumps, that provide a lower grade of heat, will not be a practical alternative in most commercial scenarios. One answer then is to use a combination of two or three technologies to provision a high heat, low cost system.

So, let’s consider the advantages of the hybrid approach, which, at the most basic for heating systems consist of two heat generators, of which at least one is operated with renewable energies and one with fossil fuel. Often, a hybrid heat pump system consists of a heat pump (air source) designed for a system part load (base load) and a gas condensing boiler for peak load, for example during the cold, dark winter months. In a fully hybrid heat pump system, both heat generators can cover the entire heating load, where the energy sources can be freely selected according to definable criteria including efficiency, emissions and price.

Compared to a conventional combustion heating system a hybrid system will require two heat generators and two energy connections, meaning even when there is a pre-existing gas connection, there will be issues of logistics, space requirements and a higher complexity of the plant. That requires more effort and expertise from the system designer, supplier and installer which leads to a 50 to 60%. higher CAPEX cost compared to a pure condensing heating system. So, what are the advantages that outweigh these initial costs?

A hybrid heat pump/gas boiler system is able to reduce the maximum power consumption of a system by smartly balancing the heat generators for greater efficiencies and lower operational costs whilst guaranteeing high system temperatures to ensure the comfort of those still living or working in the building during refurbishment work. If the hybrid system is also equipped with buffer tank and domestic hot water tank the heat pump can achieve a high proportion of cover for space heating and DHW heating increasing the profitability of the system.

A hybrid heating system cannot only be cost-effectively controlled, it can also be optimised for CO₂ emissions by selecting the optimal (ecological) heat generator whenever possible via an energy management system that incorporates smart metering.

Should the building envelope subsequently be renovated, the required heating load decreases and the existing gas boiler can take on less of the annual heating work or eventually could be put out of operation.

That said, at the time of writing the spark spread - the difference between the wholesale market price of electricity and its cost of production using natural gas - is calculated to be 5.7. For a heat pump to break even against a typical 90% efficient gas boiler, the heat pump must demonstrate a COP of 5.15. Currently we see high performing commercial heat pumps exhibiting a COP that ranges from 2.9 to a very high 4.7 due to variance in seasonal external temperature and heating flow temperature, meaning there will be times when reverting to gas technology is still more advantageous in terms of reducing running costs. There will, of course, also be projects where renewables are closed out due to limitations of either the site or the technology.

This is particularly relevant to large buildings where a heat pump alone is simply not suitable. These projects need an additional, high grade source of heat. Now, that essentially takes you to gas, but if the building is big enough, after the heat pump, but before the gas, can sit m-CHP to provide low NOₓ and very low running costs.

We can also make a case for using CHP in existing buildings which already have gas boilers and do not have the electrical supply needed to utilise a heat pump. Again, it does not make sense to fit just a heat pump. But we do not want to use CHP to offset low temperature heat pumps, it has to sit after a heat pump, offsetting the gas heater. Such an approach will still offer some carbon savings, definitely cost savings and, if that CHP is a low NOₓ appliance when compared to the boiler, then we also have NOₓ saving. At worst such a system is going to be carbon neutral but NOₓ and cost effective, especially as m-CHP, along with solar photovoltaic panels under the new Smart Export Guarantee (SEG) legislation can now profit from exporting excess electricity to the grid.

The move towards all electric in smaller buildings also reopens the door for solar thermal with better payback case and better carbon savings. Used in conjunction with low temperature ASHPs in an arrangement to ensure that it offsets the high grade source, it offers an alternate hybrid approach that does not require CHP.

We believe gas fired boilers and m-CHP will continue to play a necessary role as part of many hybrid systems, supporting solar thermal and ASHPs to achieve effective water temperatures for commercial heating applications whilst balancing running costs and savings.

For energy managers, hybrid heating provides the option of switching between heat generators to improve operations and optimise the system for reduced CO₂ emissions. Add the ability to provide greater efficiencies through smart metering and use of flexible electricity tariffs, and hybrid systems also offer a method for helping address the future of the grid through export and load balancing. This is one more way to tackle climate change that could be a real game-changer for businesses being held up as a major guilty party when it comes to the continued generation of greenhouse gasses.

For the facilities manager, it’s a practical step on the road to achieving carbon neutral building stock. One that addresses aging and environmentally unfriendly heating systems, improving operations, delivering on corporate social responsibility and, by addressing the future of the grid, provides a way of supporting wider efforts to tackle climate change. It is also relatively quick to implement, retaining use of existing infrastructure to be less invasive and more cost-effective to operate. Critically, it gives managers of older buildings more options when it comes to implementing long-term energy resolutions to 2050 and beyond.